Unique workholding grippers that allow for complete BlueGrip™ workholding adhesive curing.

Unique workholding grippers that allow for complete BlueGrip™ workholding adhesive curing.

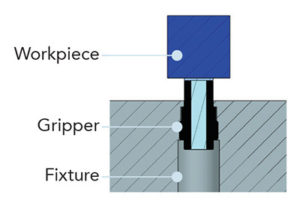

Blue Photon’s workholding grippers are a patented, load bearing and light transmitting fixture components. Grippers are the foundation of the Blue Photon grip technology.

Head-In Gripper

- Insert into fixture from the backside.

- Can be retracted during workplace loading.

- Use with gripper internal and external inserts.

- Debonds with 1/4 turn twist or hot water soak.

How Our Grippers Work

The grippers are inserted into a fixture. The workpiece is secured to the grippers with BlueGrip workholding adhesive, which is cured with UV light transmitted through the core of the gripper.

Our Grippers

Gripper Size Comparison

Effective Jan. 1, 2022, Blue Photon discontinued the following imperial products. Learn more below…

Metric

Small Head-In Gripper

Part#: 14130, 14131

Part #: 14130 – Standard Small Head-In Gripper

Part #: 14131 – Small Corrosion Resistant Head-In Gripper

Features

- To hold small size workpieces for lighter duty machining.

- Insert into fixture from the backside.

- Can be retracted during workplace loading.

- Debonds with 1/4 turn twist, hot water soak, or dry ice blasting.

- Average tensile holding power with BlueGrip S2 workholding adhesive is 150 lbs.*

- Use P/N 14131** where deionized water is used.

*Testing done under controlled conditions. **CNC spindle mounted cleaning tool cannot be used with corrosion resistant grippers.

Small Head-Out Gripper

Part#: 14230, 14231

Part #: 14230 – Standard Small Head-Out Gripper

Part #: 14231 – Small Corrosion Resistant Head-Out Gripper

Features

- To hold small size workpieces.

- Use in applications for simplified fixture design.

- Insert into fixture from the topside.

- Cannot be retracted during workplace loading.

- Debonds with hot water soak, twisting, or dry ice blasting.

- Average tensile holding power with BlueGrip S2 workholding adhesive is 150 lbs.*

- Use P/N 14231** where deionized water is used.

*Testing done under controlled conditions. **CNC spindle mounted cleaning tool cannot be used with corrosion resistant grippers.

Medium Head-In Gripper

Part#: 15130, 15131

Part #: 15130 – Standard Medium Head-In Gripper

Part #: 15131 – Medium Corrosion Resistant Head-In Gripper

Features

- To hold small to medium size workpieces.

- Insert into fixture from the backside.

- Can be retracted during workplace loading.

- Debonds with 1/4 turn twist, hot water soak, or dry ice blasting.

- Average tensile holding power with BlueGrip S2 workholding adhesive is 400 lbs.*

- Use P/N 15131** where deionized water is used.

*Testing done under controlled conditions. **CNC spindle mounted cleaning tool cannot be used with corrosion resistant grippers.

Medium Head-Out Gripper

Part#: 15230, 15231

Part #: 15230 – Standard Medium Head-Out Gripper

Part #: 15231 – Medium Corrosion Resistant Head-Out Gripper

Features

- To hold small to medium size workpieces.

- Use in applications for simplified fixture design.

- Insert into fixture from the topside.

- Cannot be retracted during workplace loading.

- Debonds with hot water soak, twisting, or dry ice blasting.

- Average tensile holding power with BlueGrip S2 workholding adhesive is 400 lbs.*

- Use P/N 15231** where deionized water is used.

*Testing done under controlled conditions. **CNC spindle mounted cleaning tool cannot be used with corrosion resistant grippers.

Large Head-In Gripper

Part#: 16160, 16161

Part #: 16160 – Standard Large Head-In Gripper

Part #: 16161 – Large Corrosion Resistant Head-In Gripper

Features

- To hold medium to large size workpieces.

- Offers more surface area on gripper head for stronger holding power.

- Insert into fixture from the backside.

- Can be retracted during workplace loading.

- Debonds with 1/4 turn twist, hot water soak, or dry ice blasting.

- Average tensile holding power with BlueGrip S2 workholding adhesive is 605 lbs.*

- Use P/N 16161** where deionized water is used.

*Testing done under controlled conditions. **CNC spindle mounted cleaning tool cannot be used with corrosion resistant grippers.

Large Head-Out Gripper

Part#: 16260, 16261

Part #: 16260 – Standard Large Head-Out Gripper

Part #: 16261 – Large Corrosion Resistant Head-Out Gripper

Features

- To hold medium to large size workpieces.

- Use in applications for simplified fixture design.

- Insert into fixture from the topside.

- Cannot be retracted during workplace loading.

- Debonds with hot water soak, twisting, or dry ice blasting.

- Average tensile holding power with BlueGrip S2 workholding adhesive is 605 lbs.*

- Use P/N 16261** where deionized water is used.

*Testing done under controlled conditions. **CNC spindle mounted cleaning tool cannot be used with corrosion resistant grippers.

| Part # | Description | Application |

|---|---|---|

| Grippers | ||

| 14130 | Standard Small Head-In Gripper | To use with small size workpieces. |

| 14131 | Small Corrosion Resistant Head-In Gripper | To use with small size workpieces where deionized water is being used. |

| 14230 | Standard Small Head-Out Gripper | To use with small size workpieces. |

| 14231 | Small Corrosion Resistant Head-Out Gripper | To use with small size workpieces where deionized water is being used. |

| 15130 | Standard Medium Head-In Gripper | To use with small to medium size workpieces. |

| 15131 | Medium Corrosion Resistant Head-In Gripper | To use with small to medium size workpieces where deionized water is being used. |

| 15230 | Standard Medium Head-Out Gripper | To use with small to medium size workpieces. |

| 15231 | Medium Corrosion Resistant Head-Out Gripper | To use with small to medium size workpieces where deionized water is being used. |

| 16160 | Standard Large Head-In Gripper | To use with medium to large size workpieces. |

| 16161 | Large Corrosion Resistant Head-In Gripper | To use with medium to large size workpieces where deionized water is being used. |

| 16260 | Standard Large Head-Out Gripper | To use with medium to large size workpieces. |

| 16261 | Large Corrosion Resistant Head-Out Gripper | To use with medium to large size workpieces where deionized water is being used. |

Our Gripper Inserts

Insert Size Comparison

Metric

Internal Inserts

Part#: 24100, 25100, 26100

Part #: 24100 – Small internal insert to use with aluminum tooling to prevent thread galling while twist debonding, use with P/N 14130.

Part #: 25100 – Medium internal insert to use with aluminum tooling to prevent thread galling while twist debonding, use with P/N 15130.

Part #: 26100 – Large internal insert to use with aluminum tooling to prevent thread galling while twist debonding, use with P/N 16160.

Features

- Use gripper inserts to protect aluminum fixtures from thread galling.

- Made from hardened steel with a black oxide finish.

- Install with thread locker.

- Screws in from the bottom.

External Insert Assemblies

Part#: 24200, 25200, 26200

Part #: 24200 – Small external insert to use with aluminum tooling to prevent thread galling while twist debonding and to allow for adjustability, use with P/N 14130.

Part #: 25200 – Medium external insert to use with aluminum tooling to prevent thread galling while twist debonding and to allow for adjustability, use with P/N 15130.

Part #: 26200 – Large external insert to use with aluminum tooling to prevent thread galling while twist debonding and to allow for adjustability, use with P/N 16160.

Features

- Includes the gripper insert and insert nut.

- Use to increase standoff from the fixture and/or to protect aluminum fixtures from thread galling.

- Inserts allow for additional flexibility for exact gripper height positioning.

- Made from hardened steel with a black oxide finish.

- Screws in from the top.

External Fixed Inserts

Part#: 24211, 25211, 26211

Blue Photon’s external fixed inserts allow for simple installation of the grippers at the required height for maximum holding power.

Part #: 24211 – Large gripper external insert for small head-in gripper, use with P/N 14130.

Part #: 25211 – Large gripper external insert for medium head-in gripper, use with P/N 15130.

Part #: 26211 – Large gripper external insert for large head-in gripper, use with P/N 16160.

Features

- Designed specifically for the Grip Pallets.

- Available for use with small, medium and large head-in grippers.

- Made from hardened steel with a black oxide finish.

- Screws in from the top.

External Fixed Insert Assemblies

Part#: 24219, 25219, 26219

Blue Photon’s external fixed insert assemblies allow for simple installation of the grippers at the required height for maximum holding power.

Part #: 24219 – With small head-in gripper.

Part #: 25219 – With medium head-in gripper.

Part #: 26219 – With large head-in gripper.

Features

- Designed specifically for the Grip Pallets.

- Available for use with small, medium and large head-in grippers.

- Made from hardened steel with a black oxide finish.

- Screws in from the top.

| Part # | Description | Application |

|---|---|---|

| Inserts | ||

| 24100 | Small Internal Insert | To use with aluminum tooling to prevent thread galling while twist debonding, use with P/N 14130. |

| 25100 | Medium Internal Insert | To use with aluminum tooling to prevent thread galling while twist debonding, use with P/N 15130. |

| 26100 | Large Internal Insert | To use with aluminum tooling to prevent thread galling while twist debonding, use with P/N 16160. |

| 24200 | Small External Insert Assembly | To use with aluminum tooling to prevent thread galling while twist debonding and to allow for adjustability, use with P/N 14130. |

| 25200 | Medium External Insert Assembly | To use with aluminum tooling to prevent thread galling while twist debonding and to allow for adjustability, use with P/N 15130. |

| 26200 | Large External Insert Assembly | To use with aluminum tooling to prevent thread galling while twist debonding and to allow for adjustability, use with P/N 16160. |

| 24211 | External Fixed Insert | Small head-in gripper. |

| 25211 | External Fixed Insert | Medium head-in gripper. |

| 26211 | External Fixed Insert | Large head-in gripper. |

| 24219 | Head-In Gripper & External Fixed Insert Assembly | Small head-in gripper. |

| 25219 | Head-In Gripper & External Fixed Insert Assembly | Medium head-in gripper. |

| 26219 | Head-In Gripper & External Fixed Insert Assembly | Large head-in gripper. |

Our Gripper Accessories

Ratchet and Sockets

Part#: 50200, 52200, 51525, 54595, 58595

Grippers debond with 1/4 turn twist of ratchet.

Part #: 50200 – 3/8 drive ratchet use with sockets 54595 and 58595

Part #: 52200 – 1/4 drive ratchet use with socket 51525

Part #: 51525 – 1/4 drive ratchet 8 mm thin wall socket use with small grippers

Part #: 54595 – 3/8 drive 12 mm thin wall socket use with medium grippers

Part #: 58595 – 3/8 drive 14 mm thin wall socket use with large grippers

Shims

Part#: 51330, 51430, 55330, 55430, 58330, 58430

To adjust a gripper height while using the head-in grippers.

Part #: 51330 – Small shim, .005″ thickness

Part #: 51430 – Small shim, .010″ thickness

Part #: 55330 – Medium shim, .005″ thickness

Part #: 55430 – Medium shim, .010″ thickness

Part #: 58330 – Large shim, .005″ thickness

Part #: 58430 – Large shim, .010″ thickness

| Part # | Description | Application |

|---|---|---|

| Gripper Accessories | ||

| 50200 | 3/8 Drive Ratchet | To use with sockets P/N 54595 and 58595. |

| 52200 | 1/4 Drive Ratchet | To use with socket P/N 51525. |

| 51525 | 1/4 Drive 8 mm Thin Wall Socket | To use with small grippers. |

| 54595 | 3/8 Drive 12 mm Thin Wall Socket | To use with medium grippers. |

| 58595 | 3/8 Drive 14 mm Thin Wall Socket | To use with large grippers. |

| 51330 | Small Shim, .005" Thickness | To adjust a gripper height while using the head-in grippers. |

| 51430 | Small Shim, .010" Thickness | To adjust a gripper height while using the head-in grippers. |

| 55330 | Medium Shim, .005" Thickness | To adjust a gripper height while using the head-in grippers. |

| 55430 | Medium Shim, .010" Thickness | To adjust a gripper height while using the head-in grippers. |

| 58330 | Large Shim, .005" Thickness | To adjust a gripper height while using the head-in grippers. |

| 58430 | Large Shim, .010" Thickness | To adjust a gripper height while using the head-in grippers. |

We will accept orders for the imperial gripper and insert products until the discontinued date and afterwards until stock is depleted in order to allow for future planning by our customers; however, after the discontinued date, a special order for current customers is available upon request, please allow up to four weeks for special orders. For the suggested replacements please see our metric gripper and insert products.

Contact your Blue Photon sales representative if you have additional questions.