Below is a list of frequently asked questions about Blue Photon’s workholding products. Please contact us for assistance, a demo or feel free to download technical specifications.

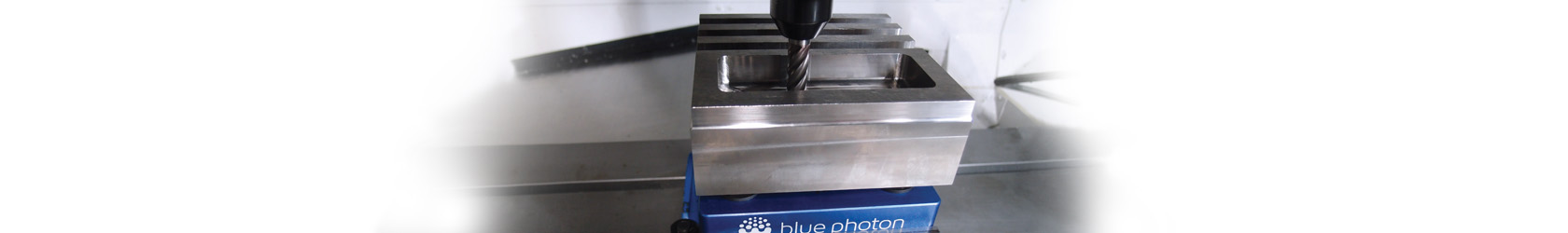

What is the Blue Photon system?

The Blue Photon system is a new revolutionary workholding product that utilizes BlueGrip™ workholding adhesives and UV light to bond and grip almost any part for machining without clamping.

What makes it unique?

It provides the most versatile method of fixturing of complex geometries while at the same time providing more cutting tool access than any other workholding product on the market.

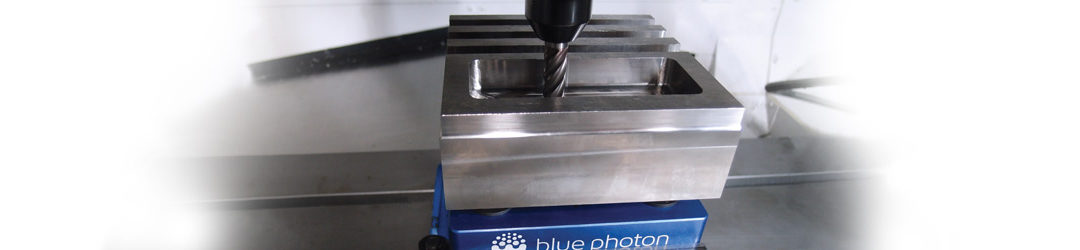

What types of machining can I do using the Blue Photon system?

The Blue Photon system is strong enough to withstand heavy milling, turning, grinding, EDM, ECM, 3D printing/additive manufacturing and more.

How long does it take to cure the BlueGrip™ workholding adhesive?

The S2 and S3 adhesives are typically cured in 60 seconds, the S2-F is cured in 120 seconds. The exception to this is when Blue Photon’s right angle adapter is utilized, in which case the recommended cure time is 90 seconds for S2/S3 and 150 seconds for S2-F.

How thick can the adhesive gap be?

The gap between the part and the gripper can range from .5mm to 3mm. The ideal gap is .5mm for small grippers and 1mm for medium and large grippers. Learn more about the adhesive and adhesive joint here at our Technical Data center.

Will the adhesive hold up to cutting fluids and EDM oil?

The adhesive can be used in water and most cutting fluids.

How hot can the part get?

It is recommended that the adhesive joint temperature remains below 30° C in order to achieve maximum holding strength. It is the temperature of the adhesive joint itself, not the part, that affects the holding strength.

How many grippers do I need?

There are several factors involved when deciding on the number of grippers to use. The forces applied to the part during machining are generally unknown by most users. Your regional sales representative can help you engineer a solution for your unique application.

How do I release the part?

The part is released from the fixture by simply twisting the grippers to break the workholding bond. The part can also be released using hot water.

How do I clean off the cured adhesive?

Heat, hot water or steam along with peeling will remove the adhesive from the part and the grippers. Blue Photon offers steamers, hot water washers and an adhesive grinder that can be used in a CNC machining center to automatically remove the adhesive from the grippers. Dry ice blasting will remove residual cured adhesive from the part as well.

What materials will the adhesive hold?

The BlueGrip workholding adhesive will hold steel, titanium, aluminum, composites, ceramics, plastics and many other materials.

For information on more materials and other Technical Data, visit our Technical Data resource center.