Workholding Technology for Ceramic Machining

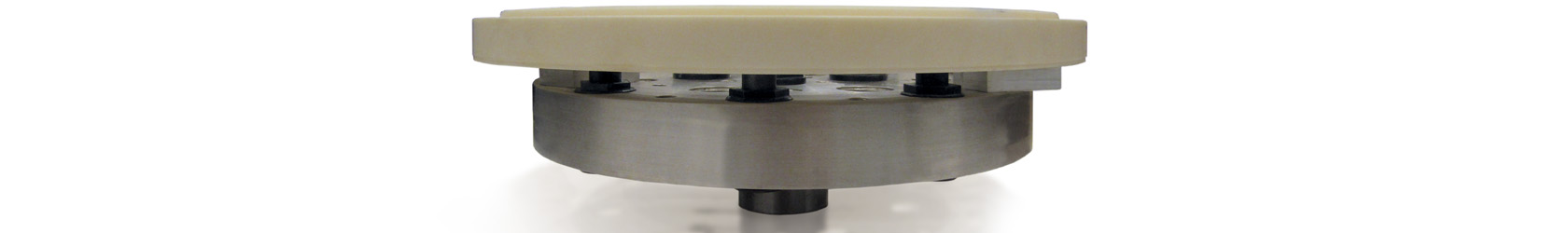

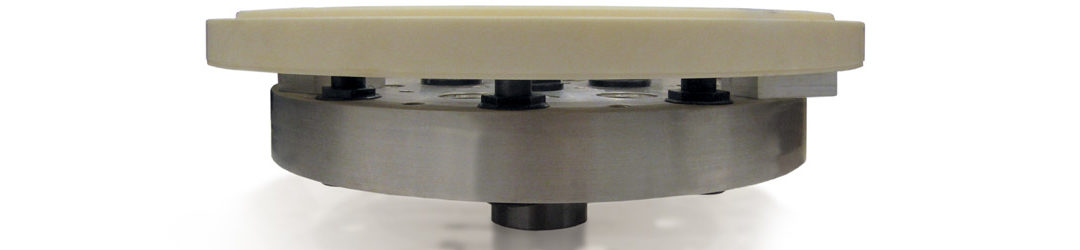

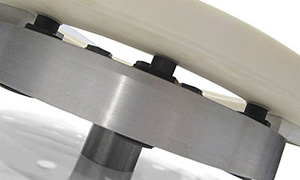

Blue Photon’s ultraviolet (UV) technology solves workholding struggles by eliminating scrap and time caused by other forms of workholding, ensuring that the surface integrity of the material is not affected. Blue Photon grippers are inserted into a fixture where the workpiece is secured to the grippers with BlueGrip™ workholding adhesive. The BlueGrip adhesive is cured with UV light transmitted through the core of the gripper. Blue Photon’s grippers are a patented, load bearing, and light transmitting fixture component.

The BlueGrip workholding adhesive allows technical ceramic manufacturers to:

The BlueGrip workholding adhesive allows technical ceramic manufacturers to:

- Hold fragile, delicate and complex technical ceramic materials for machining

- Eliminate wax, resin, and mechanical clamp operations

- Create better parts while reducing scrap and lowering manufacturing costs

Blue Photon grippers allow for complete workholding on ceramic parts without the use of clamps.

Application Example

A manufacturer of engineered ceramics needed to find a way to machine technical ceramic more effectively. Fine ceramics can be difficult to hold because of the part complexity. The process of wax, resin, and mechanical clamps have many set-up operations, making the whole machining process to hold ceramic very time consuming. The solution was to use Blue Photon’s UV workholding technology to solve their holding struggles by eliminating scrap and time caused by other forms of workholding, ensuring that the surface integrity of the ceramic was not affected. By implementing the Blue Photon system, the manufacturer was also able to increase output due to the reduced number of operations.

Contact us to learn more!