Not Your Grandpa’s Workholding

Not Your Grandpa’s Workholding

For generations, mainstream workholding has essentially remained the same, squeezing the part against hard fixture points and supporting compliant areas with work supports. This method has served the metal removal industry well for the most part. However, with today’s freedom to design and machine complex workpieces coupled with new materials, holding parts for machining has become an increasingly difficult proposition.

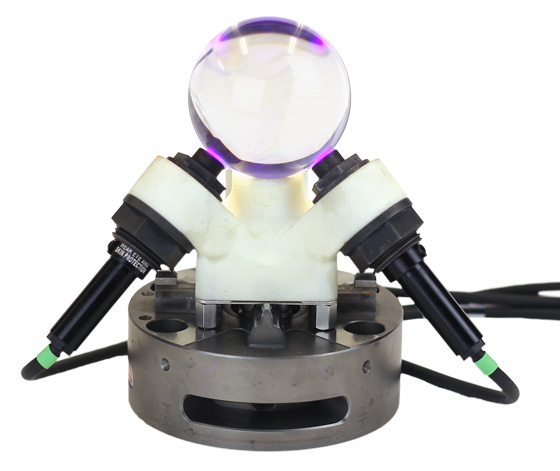

Blue Photon’s system alleviates the problems caused by squeezing the part, namely: part distortion; defacing the part; chipping a brittle part; blocking the cutting tool and coolant access to the part.

How we fix the problems of everyday workholding:

- Distortion from clamping — Eliminate the clamps!

- Part defacing — Eliminate the clamps!

- Chipping a brittle part — Eliminate the clamps!

- Blocking cutting tool and coolant access to the part – Eliminate the clamps!

Why make the switch to Blue Photon?

Blue Photon’s system can aid you in holding your hard-to-hold part by eliminating the issues you face when trying to hold the part during machining. Slipping, sliding and squishing are gone forever!

Characteristics of parts using the Blue Photon workholding system:

- Additive manufactured 3D printed parts.

- Castings.

- Thin-walled parts.

- Parts that are easily distorted.

- Brittle or fragile parts.

- Parts with multiple machined surfaces.

- Small tolerance parts.

Say Goodbye to Clamps!

Watch this interview of our European distributor discussing the clamp-free capabilities of the Blue Photon system.

Some of the benefits realized by using the Blue Photon workholding system include:

- Five-sided access and in some cases six-sided access to the workpiece.

- Elimination of workpiece distortion.

- Reduction in total set up time.

- Reduction or elimination of machining chatter.

- Simplification of fixture design and reduction in fixturing cost.

- Elimination of clamping lugs from castings and the need to subsequently remove them.

- Allows for easy automation of hard-to-hold parts.

- Adhesive gap compensates for part variation.

- Reduction in the number of operations is often realized.